Transformative Engineering Solutions: From Prototype to Production with Uncompromised Integrity

-

"ONE" Art-Industrial Collection | Custom 3D Metal Typography & Functional Integration

Regular price HK$99,999.00Regular priceUnit price perHK$99,999.00Sale price HK$99,999.00 -

Custom Aluminum Stamping Containers & Molds | China OEM Factory

Regular price HK$99,999.00Regular priceUnit price perHK$99,999.00Sale price HK$99,999.00 -

Custom Artistic Metal Vases | Fluid Spinning & Multi-Surface Finishing

Regular price HK$99,999.00Regular priceUnit price perHK$99,999.00Sale price HK$99,999.00 -

Custom Automotive Front Grilles | Multi-Style Design & OEM+ Solutions

Regular price HK$99,999.00Regular priceUnit price per

Slow Wire EDM Workshop Demonstration

Sodick RS Series Precision Wire EDM | Micron-Level Machining System

This Japan-manufactured Sodick RS series wire-cut EDM machine delivers ±1.5μm accuracy for complex geometries through advanced linear motor drive technology. Equipped with AI-powered CNC system and automatic wire threading, it handles heavy workpieces up to 90kg, ideal for aerospace components, medical device tooling, and precision mold inserts.

Key Specifications:

Ultra-Precision Performance

- Cutting Accuracy: ±1.5μm (ISO 9013 certified)

- Surface Finish: Ra≤0.8μm (Mirror-cut mode)

- Max Workpiece: 500×350×200mm (L×W×H)

Smart Operation

- 7" Touchscreen with real-time energy monitoring

- RS-232C interface for CAD/CAM integration

- Auto wire-break recovery (MTBF≥2000hrs)

Industrial Safety

- CE-certified full enclosure

- Triple safety system with emergency stop

- Deionized water circulation (≥50kΩ·cm)

Compatible Materials:

Tungsten carbide (HRC62+), titanium alloys, hardened tool steels

Medium-Speed Wire EDM Workshop Demonstration

PowerCraft Medium Wire EDM Services | Precision Cutting Solutions

Your Strategic Manufacturing Partner

🔧 Micro-Feature Specialists

- 0.15mm wire cutting: Medical device micro-holes (orthopedic implants)

- ±0.02mm repeatability: Automotive die inserts mass production

⚡ Complex Geometry Masters

- 30° taper cutting: Aerospace sensor brackets with multi-angle slots

- 300mm thick machining: Hydraulic valve block deep cavities

Cross-Industry Expertise

▶ Electronics: 5G waveguide micro-grooves (Ra1.6μm finish)

▶ New Energy: Fuel cell bipolar plate channels (Ti alloy/graphite)

▶ Tooling: Mobile device nano-texture molds (1000+ patterns/10mm²)

RUIJUN FT-400 Medium Wire EDM

Core Competencies

🔧 Micron-Level Precision

- ±0.015mm repeatability for medical bone screws (Φ0.5mm holes)

- Ra≤1.8μm surface finish on 5G waveguide channels

400mm wide stroke for EV battery frames (350×250mm plates)

30° taper cutting on aerospace titanium brackets

Industry Solutions

▶ Electronics: 0.2mm slots in ceramic substrates (edge chipping <5μm)

▶ Medical: Surgical tool joints (±0.01mm fit tolerance)

▶ Automotive: Gear mold inserts (HRC60+ hardened steel)

Technical Highlights

- 7" touchscreen with real-time energy analytics

- Yellow alert module for wire consumption tracking

- Yellow coolant tank with 3-stage filtration (≤20μm particles)

- 48hr continuous operation capability

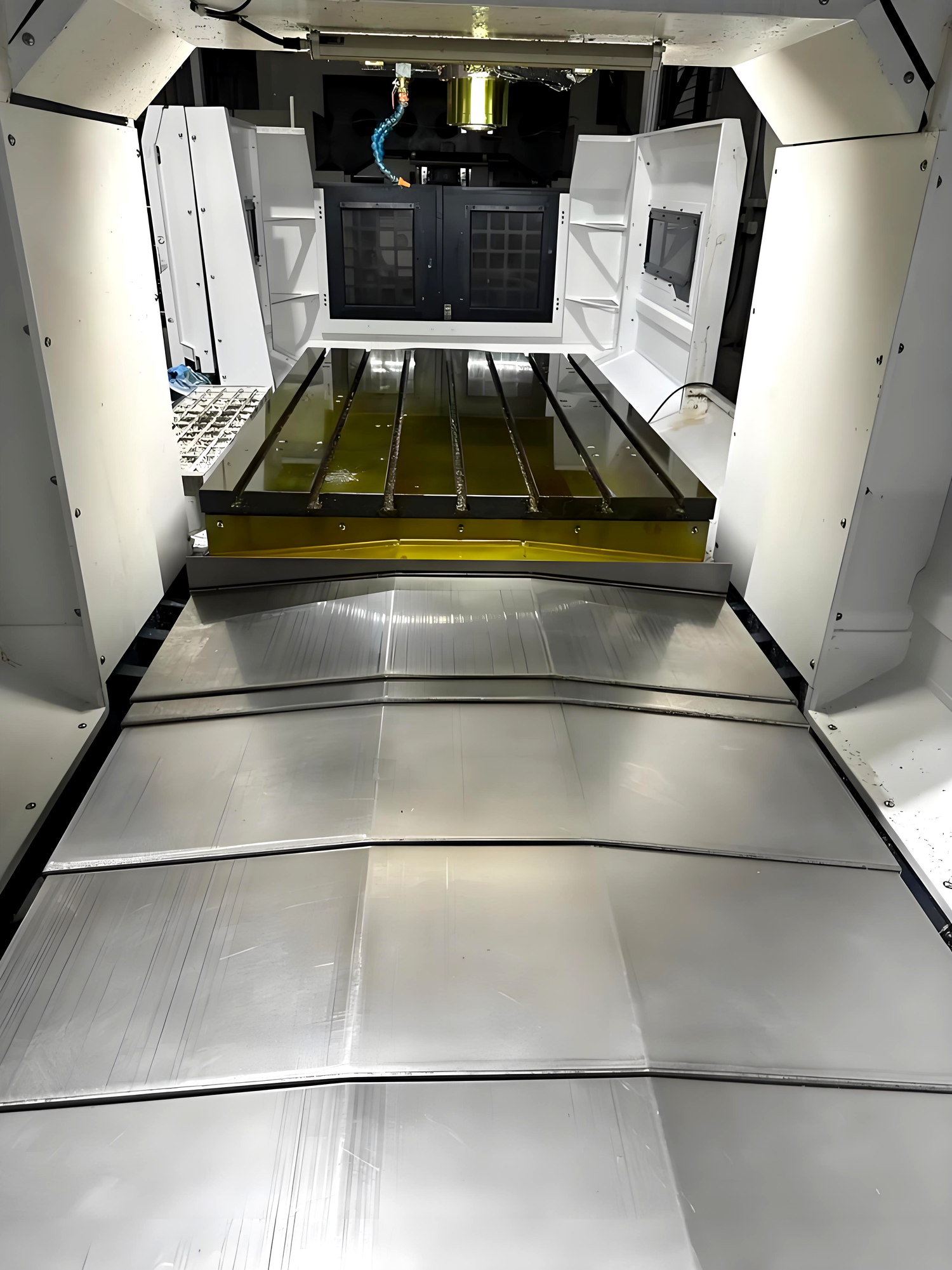

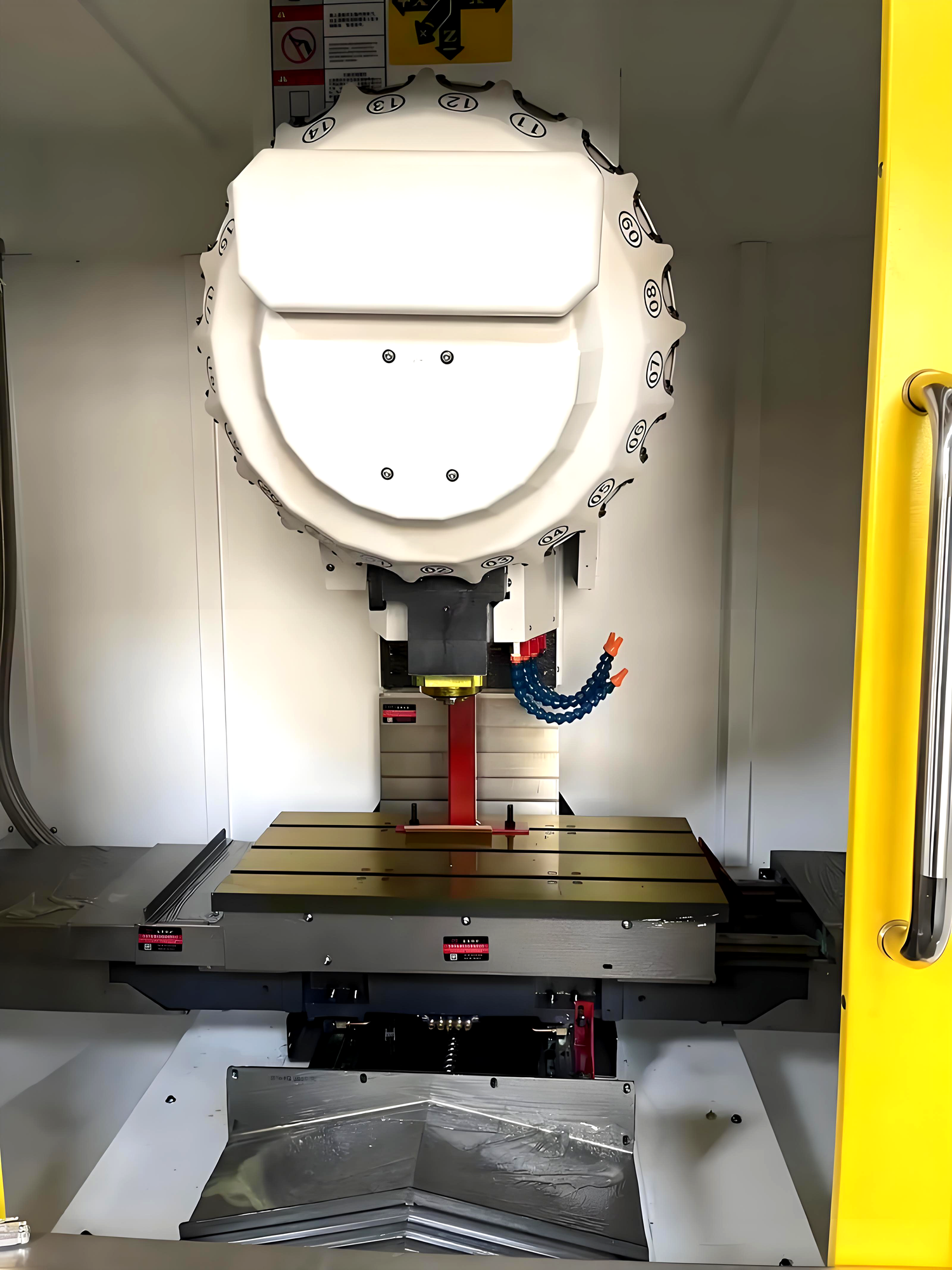

Automated CNC Machining Center Production Showcase

Core Service Advantages

4-axis simultaneous machining: Achieve ±0.01mm accuracy on aerospace impellers (visible in background machine operations)

Micro-milling expertise: Medical implant micro-grooves down to 0.2mm width (supported by LED-lit precision tooling systems)

Caption

Multi-Material Mastery

- Metal processing: Aluminum/Titanium alloys (mirror finish Ra 0.4μm)

- Engineering plastics: PEEK/PTFE components with 0.05mm thin-wall structures

Industry-Specific Solutions

▶ Automotive:

- Transmission housings (DNM 4050's 1,500mm X-axis capacity)

- EV battery cooling plates (high-speed drilling @ 8,000 RPM)

▶ Electronics:

- 5G antenna molds (QN 4441-coded projects with <3μm parallelism)

- Semiconductor wafer chucks (44-56mm bore precision boring)

▶ Energy Sector:

- Turbine blade root slots (88mm deep cavity machining)

- Hydraulic valve blocks (355mm³ complex flow paths)