Sheet Forming

Stamping

- Automotive body panels

- Electronic connector terminals

- Household appliance hardware

Sheet Metal Fabrication

- Enclosure customization (19" rack standards)

- Architectural curtain wall units

- Aerospace sheet metal components

Spinning

- Satellite dish reflectors

- Precision lamp reflectors

- Pressure vessel heads

Molten Forming

Die Casting

- Automotive: Engine housings/Transmission parts

- Electronics: Heat sinks/Structural frames

- Industrial: Pump bodies/Power tool casings

Injection Molding

- Electronics: Phone casings/Connectors

- Medical: Syringes/Diagnostic devices

- Automotive: Interior trim/Light covers

- Consumer: Packagingcontainers/Household parts

Core Advantages

-

Die Casting

- Single-step complex geometries

- Superior surface finish (Ra 1.6μm)

- Mass production for Zn/Al/Mg alloys

-

Injection Molding

- Micro-structures (<0.01g micro-parts)

- Multi-material compatibility (ABS/PP/Nylon/Bioplastics)

- Fully automated mass production

-

Injection Molding Core Capabilities

- Tolerance: ±0.02mm (Optical-grade)

- Thin-wall capability: 0.2mm (ABS/PC)

- Cycle rate: 200-3000 shots/hour

Collections

-

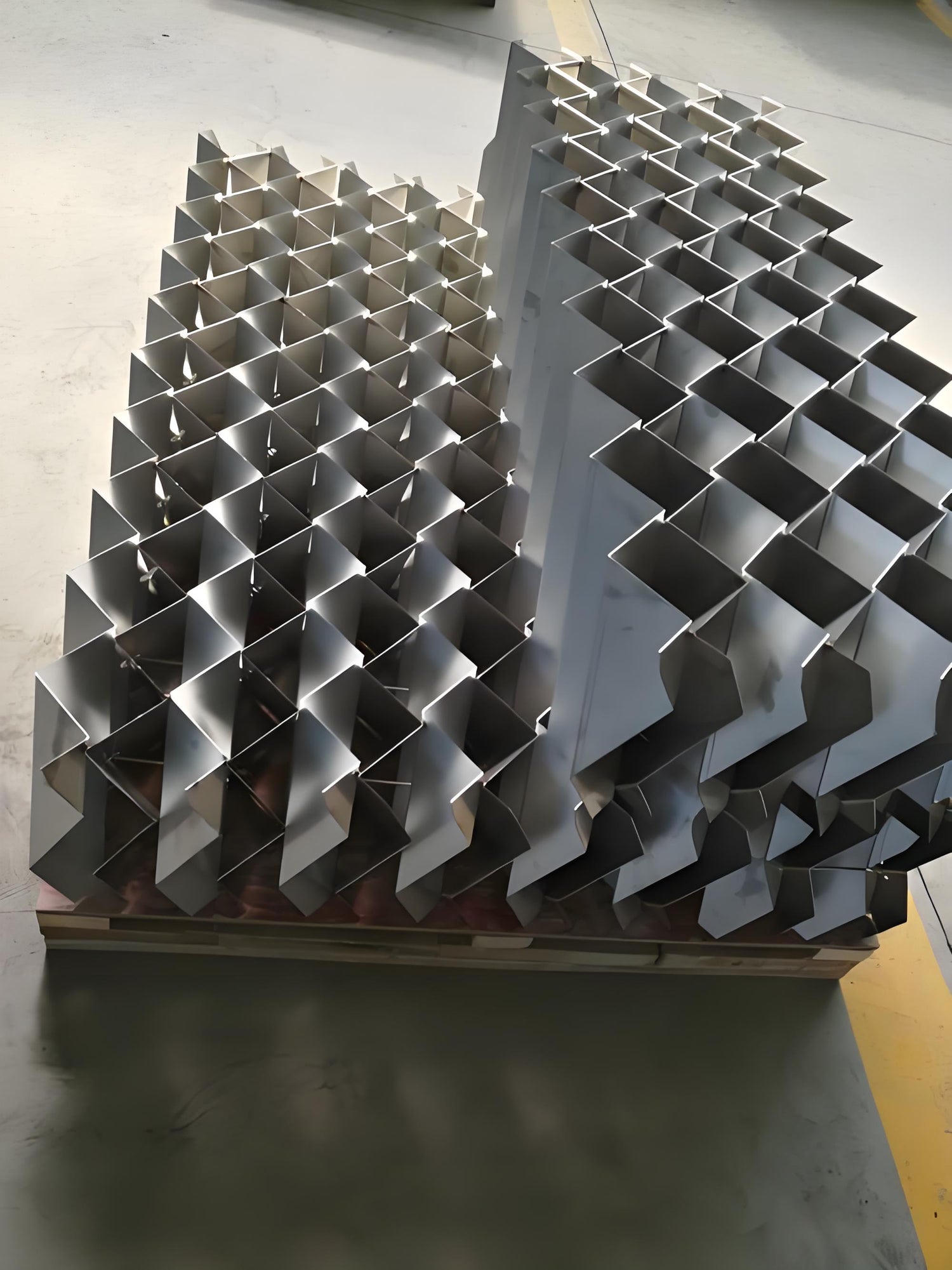

Fully Customizable Die-Casting Portfolio | Multi-Material Precision Solutions

Customization Dominance Material Freedom: Al/Mg/Zn alloys (metallic luster contrast as shown) Structural...

-

Custom Injection Molded Crafts

Create intricate acrylic/resin crafts via precision injection molding. Specialize in light-diffusing textures,...

Video

Wire Forming

Spring Manufacturing

- Automotive: Suspension springs/Clutch disc springs

- Industrial: Valve springs/Machine dampers

- Medical: Endoscope arms/Surgical tool springs

- Electronics: Connector contacts/Micro battery springs

Spring Manufacturing Core Advantages

- Load capacity: 0.1N-200kN (Customized design)

- Precision: Wire diameter tolerance ±0.01mm

- Lifecycle: 1,000,000+ cycles (Automotive-grade)